The study workshop for digital 3D technology provides students with knowledge about the applications and potentials of digital production technologies. Here the students can acquire solid and practical knowledge about production processes and apply this by working with the machines at the Fablab. This allows them to gather practical experience and to work experimentally. Some of the machines can be used independently by students, while others are used in communication with the teachers in seminars.

Alongside training for students, the Fablab provides services for research and teaching. Students and researchers learn how data is processed in the various machines. Following this, work orders can be submitted, which will then be carried out by the team at the Fablab. Along with quick availability of model elements, the service allows students to develop competence in preparing understandable data and in communicating the order data to the workshop.

Placing orders

Services are ordered by means of an online form with integrated file uploading. After checking the data, an email will be sent with information on the processing of the order. Please observe the information and templates for preparing files within the menu point “Our machines.”

You have questions related to file acceptance? We are happy to advise you by email, dreidtec[at]uni-kassel.de, telephone, 0561 804-5337/5203, or in person during our consultation hours.

The current price list can be found here as a download.

Use this link to place an order and upload data.

Currently automatic file uploading is only available for persons officially connected to the Kunsthochschule and the ASL. All others should send us files by email to auftrag.fablab[at]uni-kassel.de. Please include the following information:

- First and last name

- Invoice address

- Telephone number for possible questions

- Production method

Machines at the student workshop

The student workshop currently maintains the following machines:

These extensive facilities make it possible to offer a variety of production technologies and to realize both simple and complex projects. The goal is to provide students with practical knowledge and to deliver high quality services for research and teaching.

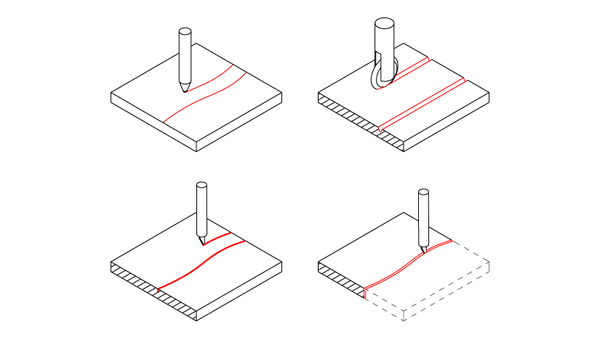

One unique characteristic of our Zünd digital cutter center is the large variety of materials that can be worked with. The modular construction allows for cutting, grooving, or marking of soft materials such as rubber, but also cardboard and sandwich panels. The maximum surface area is 1200x1700 mm.

The guidelines for the digital cutter explain which treatment methods are possible. In addition, they explain what to pay attention to when preparing files.

Downloads

Guidelines Digital Cutter

Zip archive with file templates

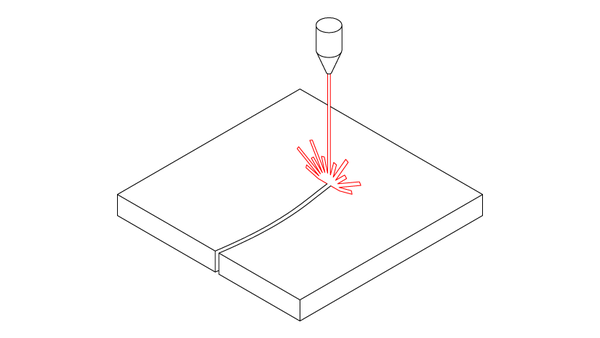

CO2 laser – The laser works with a capacity of max. 100 Watt. The size of the table surface is 960x610 mm. The versatile machine can engrave/raster engrave and cut. The laser is usually used for very intricate geometries, since the precise cutting also allows for the production of very fine structures. Principally, depending on the material, a dark discoloration of the cutting edge and a light deposit of smoke on the top and bottom of the material cannot be avoided. The contours must be assigned to the layers contained in the template.

The guidelines for laser cutting explain which treatment methods are possible. In addition, they explain what to pay attention to when preparing files. When preparing the files, our current templates should always be used.

Since the laser table is smaller than common cardboard formats, the material must be cut to a maximum size of 960x610 mm before placing it in the appropriate compartment.

The laser can of course be used both as a service as well as with a modest usage fee – after attending the appropriate course. Those interested in training for laser use can speak directly to the workshop director for an appointment.

Downloads

Guidelines for laser cutting

Zip archive with file templates

With our CNC, mill wood-based materials, hard plastic materials, and by prior arrangement even light metals can be processed. The maximum surface area is 1278 x 1537 mm.

For 2.5D milling a 2D file is used. The tool paths are created on the basis of the contours. The milling operations are to be assigned in the layers contained in the template files. The guidelines explain milling operations and how to use the templates to create the necessary files. For 3D milling a solid volume body is necessary.

2.5D milling orders can be submitted up to a maximum size of 1800x2500 mm. The size of the raw material can be submitted through us and will be developed in cooperation with the MakerLAB of the FB06.

Downloads

Guidelines 2.5D milling

Zip archive with file templates

FDM, SLS, and SLA 3D printing can be carried out in our workshop. When preparing the model parts, please observe the design rules for each procedure.

An overview with the most important data on our printers can be found in the “Infoblatt 3D Druck.” Guidelines for the individual printing procedures will be published shortly.

Downloads

info sheet 3D printing

Guidelines 3D printing

Guidelines SLA 3D printing

Director Digital Design and Production Methods Workshop

mehr…

Tutors

Franziska Brunn

Helena Bals

Madlen Beckmann

T +49 561 804 5337

E-Mail: dreidtec[at]uni-kassel.de